How an Automatic Wire Stripper for Small Electronics Can Be Instrumental

When working with small electronics, wire management is often one of the most tedious and delicate tasks. From networking cables and thermostat wires to phone lines and data cables, the variety of thin gauge wires used in small electronics can make stripping them a challenge.

As wire sizes decrease, the risk of damaging the wire itself during stripping increases, often leading to costly mistakes. This is where an automatic wire stripper, designed for precision and efficiency, can make a significant difference.

The Challenges of Stripping Small Gauge Wires

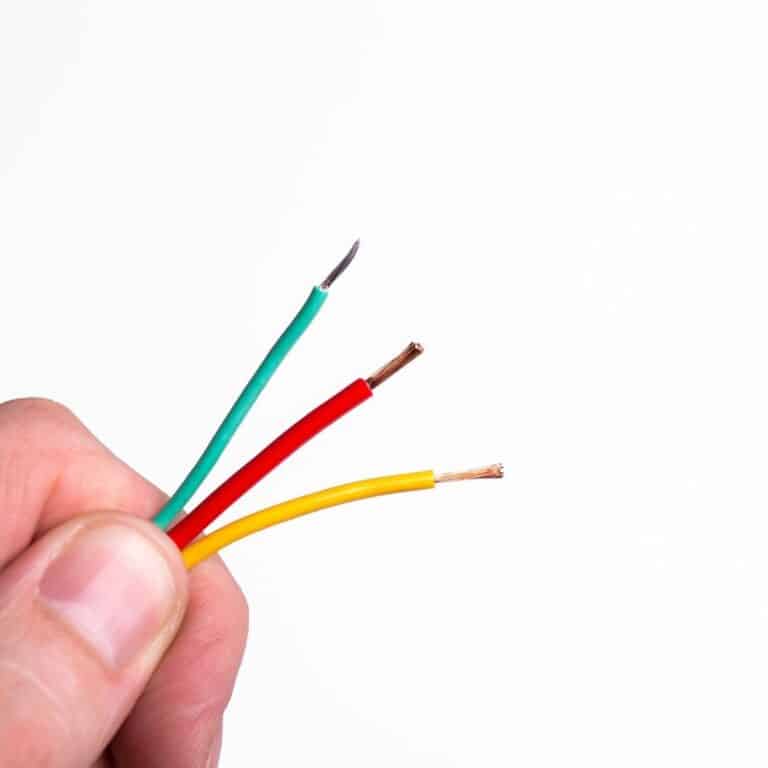

Small electronics typically require thin gauge wires, which are often much more delicate than the heavier wires used in larger electrical systems. For example, networking cables like Cat5 and Cat6, data cables, phone lines, and thermostat wiring usually range from 22 to 26 gauge in thickness. While the wires themselves may be small, the tasks they perform are critical, meaning that any damage to the wire can result in equipment malfunction or even complete failure.

Stripping these wires manually with standard wire strippers or using a knife requires precision. The smaller the wire, the more difficult it becomes to remove the insulation without damaging the wire underneath. If the insulation is not removed evenly or the wire is nicked, the connection can be compromised, leading to issues such as signal loss or short circuits.

Additionally, many small electronics feature double insulation, requiring two distinct stripping actions: one to remove the outer jacket and another to strip the internal conductors. In cramped or tight spaces, this becomes an even more challenging task. Even with experienced hands, using traditional tools in these situations can often lead to frustrations, like nicking the wire or accidentally cutting through it.

Why an Automatic Wire Stripper is the Ideal Solution

An automatic wire stripper is an excellent solution to the problems posed by small electronics wiring. Unlike manual wire strippers, which require the user to apply varying amounts of force and adjust settings for different wire gauges, automatic strippers are designed for precision and ease of use. Here’s how they help:

1. Precision Stripping for Small Gauge Wires

Automatic wire strippers are engineered to handle even the smallest gauge wires, such as 26 AWG (American Wire Gauge) and up. These strippers typically feature a built-in mechanism that adjusts to different wire gauges automatically, ensuring the insulation is stripped cleanly and evenly without damaging the wire inside. This precision is crucial, especially for small electronics, where the wires are delicate, and even a slight nick can render the wire useless.

In the case of a traditional stripper, the user may need to manually adjust the tool for each wire gauge, which can be difficult with small or very thin wires. With an automatic stripper, the gauge is recognized by the tool, and the correct stripping action is applied without any additional input from the user, reducing the likelihood of damage and ensuring that the wire remains intact.

2. Strip Multiple Wires at Once**

One of the key advantages of an automatic wire stripper is its ability to strip multiple wires at the same time. When dealing with small electronics that often involve several conductors within a single cable (for example, in network cables or thermostat wiring), being able to strip multiple wires at once can save a considerable amount of time and effort.

Standard wire strippers can only handle one wire at a time, which can be slow and cumbersome when working with projects that require stripping dozens or even hundreds of wires. With automatic wire strippers, you can feed in several wires of the same gauge at once and have them stripped in a single motion. This is especially useful when working with bundles of wires, as it reduces the need for repetitive handling and ensures uniformity across all wires.

3. Eliminate Risk of Nicking or Cutting Through the Wire

One of the most common problems with manual wire strippers is the risk of nicking the wire or cutting right through it during the stripping process. This is particularly problematic when working with small gauge wires, as the wires themselves are more fragile and susceptible to damage. If you apply too much pressure or make an incorrect cut, you can easily compromise the integrity of the wire, causing it to become ineffective.

Automatic wire strippers are designed to apply consistent pressure, ensuring that the insulation is removed without damaging the wire. The tool’s mechanism automatically adjusts to the wire size and insulation thickness, providing a more controlled and uniform cut. This significantly reduces the chances of nicking the wire or accidentally cutting through the conductor, which is a common issue when working with thin wires.

4. Works in Tight Spaces

Small electronics often require working in confined or hard-to-reach areas where space is limited. Manual wire strippers, especially traditional ones, can be bulky and difficult to maneuver in these tight spaces. Automatic wire strippers, however, tend to be more compact and efficient, making them ideal for small-scale electronics projects.

These tools can be easily used in narrow enclosures or cramped workspaces, allowing you to strip wires quickly without worrying about damaging the surrounding components. Whether you’re working inside a control panel, behind a piece of equipment, or within the limited space of a circuit board, an automatic wire stripper can be a lifesaver.

5. Double Insulation? No Problem

Many small electronics wiring systems, such as those used in networking cables or thermostat connections, feature double insulation. This requires two separate stripping actions: one to remove the outer jacket and another to strip the inner wires.

Traditional wire strippers can struggle with this task, particularly when the outer jacket is tough to remove without damaging the inner conductors. The automatic wire stripper, however, is typically capable of handling this dual-stripping requirement with ease. You can first strip away the outer jacket and then switch to stripping the individual conductors inside. The tool’s precision ensures that both actions are done cleanly without damaging the underlying wires, which is especially critical for small and delicate cables.

6. Speed and Efficiency

Time is always a valuable resource, and using the right tool can save you a significant amount of time, particularly when working on repetitive tasks like stripping wires. Manual wire stripping can be slow and inconsistent, especially when you have to adjust the tool for different wire gauges or double insulation.

An automatic wire stripper streamlines the process. With its ability to quickly strip multiple wires at once and make precise cuts, the tool increases productivity and reduces the amount of time spent on each individual wire. Whether you’re working on a single project or a high-volume job, the efficiency of an automatic wire stripper is invaluable.

Conclusion

Whether you’re dealing with networking cables, thermostat wires, phone lines, or any other small electronics wire, an automatic wire stripper will improve the quality of your work and help you avoid costly mistakes. For anyone looking to streamline their wiring process and tackle small electronics with greater efficiency, investing in an automatic wire stripper is a smart choice that will pay off in the long run.

See Also: ____________________________________________